suppling your own artwork?

We want the same thing that you want. We want your graphic files to print correctly first time and look like you meant them to.

Following these simple guidelines should help make sure that there are no delays with your printing. If anything is unclear or you just need a little more help please call us on 028 9446 4980.

Remember to check the you have set your page size to match the product that you are ordering.

For those unfamiliar with the term, “bleed” refers to an area of printed image that goes beyond the edge of the trimmed paper or board. If you would like an image or graphic to run right up to the edge of a page, then it should “bleed” over the trim line by at least 3mm. This allows some tolerance for trimming and ensures your image or graphic meets the edge precisely.

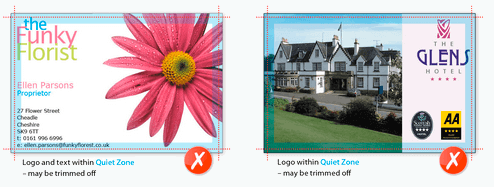

The quiet or safe zone for most of our products is 5mm, we ask that all important elements are 5mm away from the cut edge. Elements within this area may appear closer to the edge than expected when guillotined and often result in an uneven looking design.

When saving your file, ensure that you have set the artwork up in the correct colour mode for the product that you are ordering. Most products are produced in CMYK process colour. If RGB or LAB colours are found they will be converted to CMYK which will result in some colour shift. We do not recommend supplying files in RGB or LAB as it’s unlikely they’ll print as expected. Pantone Colours will also be converted to CMYK (where applicable) with the same results.

An example of an image supplied in RGB The same image once converted to CMYK

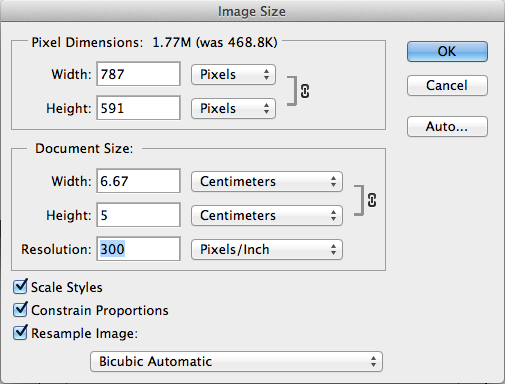

Remember to check the requirements for the resolution of images, as it may vary for different products. For CMYK process printing, your colour images should be set to 300dpi @ 100% size.

When paper is folded, its interlinking fibres are compressed on one side and stretched on the other. If the outer fibres lose their hold on each other, we see this as ‘cracking’: an opening out of the paper on the outside. This will be more visually apparent where the design includes a dark colour across the fold. If dark colours are required please upgrade to a Laminated Product which will help to reduce the appearance of cracking. This affects any product that is creased or folded such as Folded Leaflets, Creased / Shaped Flyers and Presentation Folders.

‘Chipping’ occurs when small chips / nicks appear in the print along the trim edge. This will be more noticeable when solid / darker colours are used and bled right to the edge of the design. To help reduce visible chipping, we recommend upgrading to a Laminated Product such as Laminated Business Cards / Flyers / Presentation Folders.

However, please bear in mind that recycled and uncoated stocks are more brittle and thus more prone to both cracking and chipping than our coated stocks.

Remember to check that you are saving your file in the correct format for the product that you are ordering. We would prefer you to supply us with a ‘Press Quality’ PDF.